ALSO CHECK OUT BONNET COOLING MODS

BY-PASS HOSE

IF YOU BLOCK OFF THE BY-PASS HOSE USE LATE A-SERIES (ALLEGRO MK

II 1100/1300 74-80,METRO 80>) PUMP G_MWP207 Q_QCP3710 AS THE PUMP HAS THE

PUMP BY-PASS BLOCKED OFF ANDDON'T FORGET TO FIT A THERMOSTAT BLANKING SLEEVE.

CABLE OPERATED HEATER CONTROL VALVE - M_MHV100

ELECTRIC COOLING

FANS

Why? This frees up some horse power, gives better throttle response

(due to not having to spin up the fan), reduces noise, and can increase

fuel economy.

There are 3 ways of wiring these

1, switch on the dash, if you see the engine is getting too hot, sat

in traffic or coming to the end of your journey you switch it on. This

relies on you!

2, most common, a temperature sensitive switch is fitted to the rad

(these are sometimes adjustable) when the temp get to a pre-set temp it

switches on, when it cools it goes off. This can be wired direct to the

battery so it will cool after you walk away from the car after switching

it off.

3, a temperature sensitive switch is fitted to the rad, but it

also has an override switch so if you see a long queue ahead or long slow

hill you can turn it on and make sure you have a rad full of cool water

before you need it.

WARNING WHEN REMOVING STANDARD FAN REMEMBER

TO SHORTEN PULLEY BOLTS BEFORE REFITTING THEM OR YOUR WATER PUMP CAN JAM

ELECTRIC WATER PUMPS

WHY? THIS FREES UP SOME HORSE POWER AND STOPS THE RISK OF CAVITATION ON HIGH REVING ENGINES, YOU CAN ALSO RUN IT AFTER STOPPING THE ENGINE THUS ENSURING IT COOLS DOWN PROPERLY. AS NORMALLY WHEN YOU STOP THE TEMP GOES THRO THE ROOF.

THERE ARE A FEW AFTER MARKET ONE THAT WILL DO THE JOB. USED TOGETHER

WITH THE STANDARD PUMP WITHOUT THE BELT ON OR WITH PUMP BLANKING PLATE

WITH 18mm INLET PIPE. REMEMBER IF YOUR MAKING A BLANKING PLATE YOU

MIGHT WANT A DEFLECTOR PLATE ON THE BACK OF IT TO DIRECT THE WATER AS THE

PUMP WOULD. IF NOT YOU MAY FIND NO 1 CYLINDER GETS TOO HOT AS YOUR PUMPING

THE COOL WATER STRAIGHT TO THE BACK OF THE BLOCK, YOU WON'T GET THIS PROBLEM

IF YOU LEAVE THE OLD PUMP IN PLACE.

John Benson of Davis, Craig pty. ltd. kindly sent me this and it says

what I tried to say only better. Thanks John.

The Mechanical Water Pump is one of the last mechanical components

of the modern engine which has long been considered an inefficient component

that was designed as an accessory from the very first engines. A mechanical

belt driven pump installed on your car’s engine runs at the same speed

as the engine regardless of engine temperature. Example: when travelling

at higher speeds, the engine require less cooling as ram air is naturally

cooling the engine however, the engine revs are high as a consequence the

mechanical water pump is providing excessive coolant whilst draining the

engine of power. Then in heavy traffic in high ambient temperatures, the

engine is only idling, low revs and so is the belt driven mechanical pump,

even though in this situation, extra coolant flow is required to cool the

engine.

With an Electric Water Pump and a EWP/Fan Digital Controller, the speed of the pump is managed commensurate with engine temperature. The Controller varies the voltage to the pump and therefore varies the coolant flow, hunting for the targeted (set) temperature. When the engine reaches the targeted temperature the Controller locks on, constantly varying the pump speed, maintaining the target temperature independent of the engine speed.

The important improvement for your vehicle’s engine is the increased power the mechanical pump ‘steals’ from your engine is returned to the drivetrain and also decreases fuel consumption. By removing the parasitic power loss of belt-driven water pump, the EWP may provide up to 10kw of extra power and additional fuel savings. The engine power used by the mechanical pump increases as the cube of its speed – so when the mechanical pump speed doubles from idle speed say; 600rpm to 1200 rpm, the power it takes increases by eight times. Then another eight times going to 2400 rpm, and so on up to maximum engine speed. It is this extra power and torque that is released by deleting the mechanical pump that provides the fuel savings that is estimated to be 3.5% to 10%.

Major European manufacturers have instigated EWP’s as standard equipment on a number of their vehicles, we have documents that show an EWP uses 90% less energy than conventional mechanical cooling systems. Other advantages include lower emissions by virtue of faster engine warm up, improved engine temperature management and the EWP running on after engine shut down helps eliminate ‘heat soak’ and improves engine life.

Weight reduction is a key requirement of any automotive manufacturer seeking fuel savings and our EWP weighs only 900 grams compared to a typical mechanical pump at 3 to 4 kg. Not only is our EWP considerably lighter when compared with a mechanical water pump and the EWP replaces several out-dated components with one environmentally friendly cooling product which once again helps improve engine performance and fuel consumption.

Davies, Craig’s range of patented Electric Water Pumps include the EBP (12v), EWP®80 (12v) and the EWP®115 (12v & 24v) in both Nylon66 and Alloy housings. The new EWP®115 (115 litres per minute) in Alloy and Nylon66 is designed to replace a vehicle’s existing mechanical belt-driven water pump and is the latest in Davies Craig’s range of simple, DIY electric water pumps which are all universal fit. Its lightweight, compact, more powerful design is suitable for all types of vehicles including small, to large plus high-performance and 4WD vehicles. It’s a vital performance product that improves engine cooling management whilst giving more power, torque and increased fuel economy. All deliver 3% to 5% improved fuel economy, increased power while lowering environmental impact by reducing emissions.

RADIATOR CAPS

It looks like it's just stops the water spilling out when you go around

bends but it is so much more. First it's a pressure seal (valve). If you're

up Everest (the mountain) you need a pressure cooker just for a hot drink

as at low pressure water boils and evaporates at lower temperatures. To

stop your cooling system water evaporating away the cap allows it to maintain

a pressure of 4-12 psi. (some systems may be different) when this is reached

the valve within the cap opens and allows the excess pressure to escape.

Conversely when it's cooling down it would create a vacuum, crushing the

system, so a second valve allows air back in to the system.

NEVER REMOVE THE CAP FROM A HOT ENGINE

OR STEAM/BOILING WATER WILL GO EVERYWHERE. IF FOR ANY REASON YOU THINK

YOU HAVE TO, THROW A HEAVY DAMP TOWEL OVER IT BEFORE YOU TRY.

THERMOSTAT HOUSINGS

FILE (OR SAW) A 1mm STEP IN THE MATING FACE OF THE HOUSING ON THE OUTSIDE OF EACH BOLT HOLE, THIS ALLOWS YOU TO LEVER IT OFF WITH OUT DAMAGING THE SEALING FACE IF IT'S STUCK(CORRODED) ON.

DRILL HOLES OUT ONE SIZE UP AND GREASE THE STUDS ON ASSEMBLY, THIS SHOULD STOP THE STUDS WELDING THEMSELVES TO THE HOUSING EVER AGAIN.

IN THEORY HOUSINGS WILL ONLY FIT ONE WAY BECAUSE THE PITCH OF THE HOLES IS DIFFERENT BUT THE LARGEST TO SMALLEST PITCH IS ONLY 2mm DIFFERENT SO IF YOU SLOT THEM SLIGHTY OR EVEN JUST OPEN THEM UP A COUPLE OF MILLIMETERS AND THEY WILL POINT ANYWAY YOU WANT.

OTHER HOUSINGS - THIS IS

PHOTOS AND DIM'NS OF VARIOUS THERMOSTAT HOUSINGS USED ON A SERIES (SPRITES

MINIS A40S MAESTRO MONTEGOS ETC.

WATER PUMPS

S_MRW3709 IS A STANDARD SOLID IMPELLER

Q_QCP3709P IS A HIGH CAPACITY FABRICATED IMPELLER

Remember whichever pump you use, if you're using

a lot of revs the pump can rotate too quickly and cause over heating through

cavitation. To overcome this you need to fit a bigger diameter pulley to

the water pump which will slow it down.

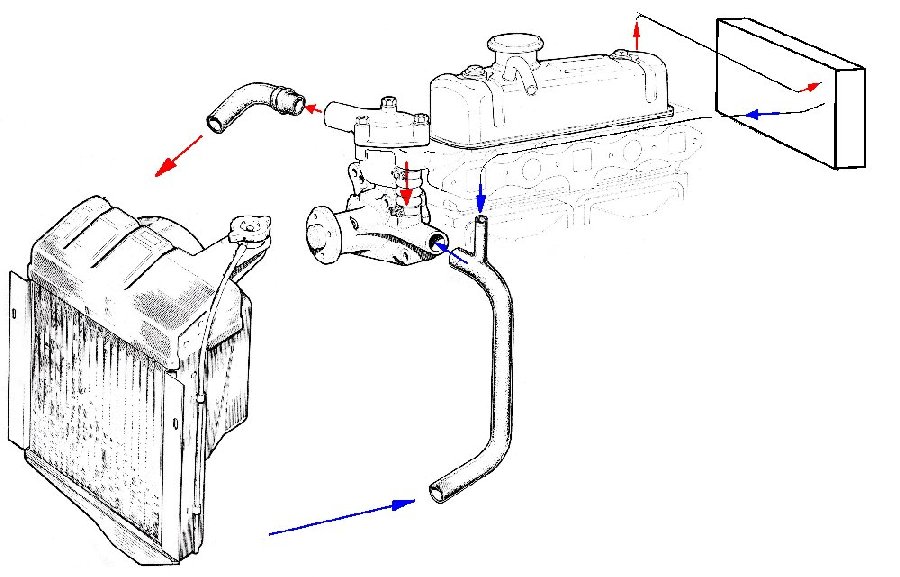

BY PASSING THE HEATER

DURING THE SUMMER OR IF YOUR RACING YOU DON'T WANT A HEATER.

RACERS USUALLY REMOVE IT TOTALLY AND REPLACE IT WITH A PIPE AND BLANKING

PLATE OVER THE AIR INTAKE.SEE DIA

I'VE SHOWN AN EARLY VERTICAL RAD HERE BUT THE PRINCIPAL IS THE

SAME FOR THE CROSS FLOW RAD.

THE THEORY OF THE COOLING SYSTEM. AS YOU CAN SEE HOT WATER FROM THE

ENGINE COMES OUT THE BY-PASS HOSE INTO THE PUMP AND ALSO THRO' THE BACK

OF THE HEAD AND INTO THE HEATER AND IS COOLED AND PUMPED BACK INTO

THE ENGINE. THIS CYCLE CONTINUES UNTIL THE ENGINE WARMS ENOUGH TO OPEN

THE THERMOSTAT WHEN HOT WATER CAN ALSO GO TO THE RAD GET COOLED AND

THEN IS PUMPED BACK IN TO THE ENGINE.

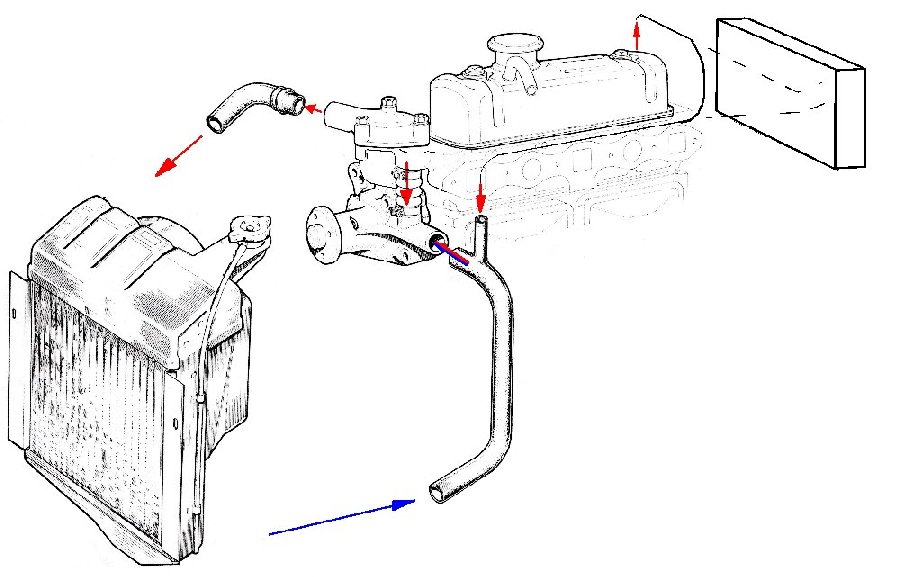

AS STANDARD YOU COULD TURN A TAP AT THE BACK OF THE HEAD THAT STOPS THE FLOW OF WATER FROM THE HEAD TO HEATER, BUT THIS CHANGES THE WATER FLOW INTERNALLY AND CAN CAUSE HOT SPOTS AROUND No 4 CYLINDER AND SO DURING THE SUMMER ALOT OF OWNERS PUT IN A PIPE FROM THE BACK OF THE HEAD THAT MISSES OUT THE HEATER. THIS IS OK BUT IT CAN CAUSE A MORE GENERAL OVER HEATING PROBLEM DURING VERY HOT WEATHER AS IT IS TAKING HOT WATER AND PUTTING IT STRAIGHT BACK INTO THE ENGINE.

AS YOU CAN SEE THIS TIME HOT WATER IS COMING FROM THE BACK OF THE HEAD

AND MIXING WITH THE COOL WATER AND GOING STRAIGHT BACK INTO THE ENGINE.

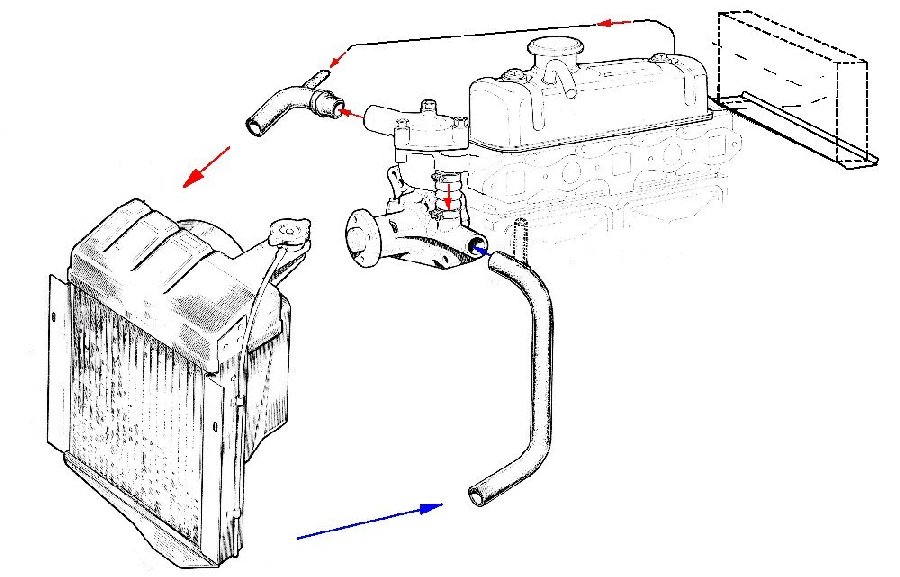

A BETTER SOLUTION IS EITHER TO GET A NEW PIPE WITHOUT

THE HEATER CONECTION OR TO BLANK THE PIPE THAT TAKES IT BACK INTO THE ENGINE

(WATER PUMP HOSE TO RADIATOR BOTTOM) AND PUT A TEE PIECE IN THE TOP HOSE

(THERMOSTAT TO RADIATOR TOP). THIS MEANS THE HOT WATER COMES OUT OF THE

BACK OF THE HEAD AND THEN GOES INTO THE RAD. ALSO THE HEATER BOX-FAN UNIT

CAN BE REMOVED AND A PLATE FITTED OVER THE CROSSMEMBER HOLES TO SEAL IT.

ANOTHER TRICK I USED ON ONE CAR WAS TOO FIT AN OIL COOLER IN THE HEATER

BOX, THUS YOU COULD CONTROL THE AIRFLOW THRO' IT AND THUS THE OIL TEMP

WITH THE FAN AND FLAP CONTROLS. ONLY ONE DRAW BACK IT MADE THE CAR VERY

HOT IN THE SUMMER